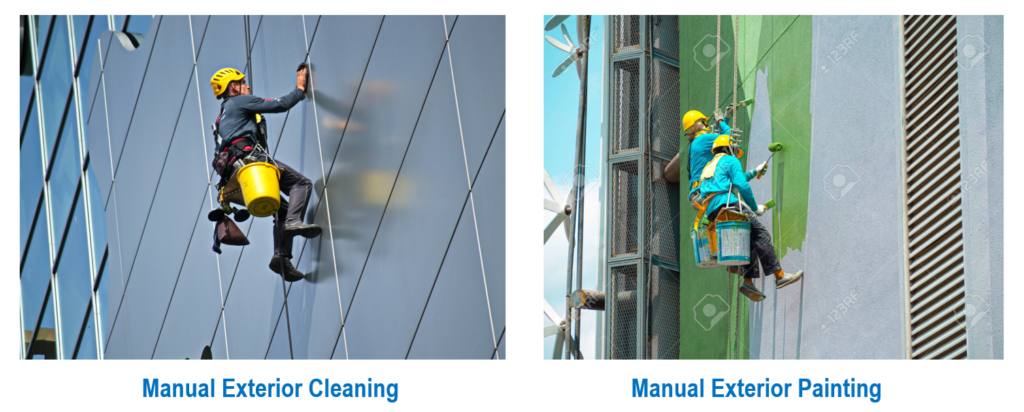

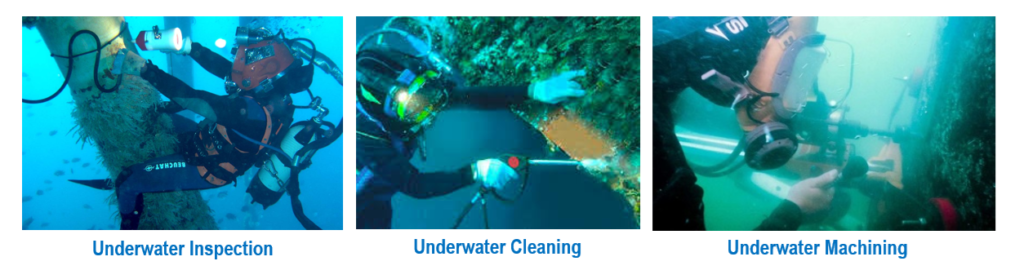

Maintenance of large structures involve tedious, frequent, time consuming and sometimes dangerous activities, such as building cleaning and painting, particularly in high height, inclined surfaces, confined spaces, or underwater.

Problems associated with the manual solutions

Most maintenance of large structures, whether it is on land or underwater, are currently performed manually. Glass/facade cleaning and wall painting in tall buildings currently use telescopic booms, hanging craddles/gondolas, and rope access. Maintenance of underwater structures currently employ skilled human divers to perform the job. These manual solutions have several drawbacks including:

Cost – Typically at least two or three workers should work side by side to perform the tasks. To accelerate the work, more workers are commonly involved; this increases the cost significantly.

Efficiency – The speed of human workers in completing the tasks cannot be much boosted due to the limitations of the human being capability.

Safety – Although the recent safety standards already make the manual solutions much safer than those in the past, potential accidents to human workers still exist. This is inherent due to the direct involvement of human workers in the tasks.

Unfeasibility in certain conditions – When the wind is strong, maintenance of a tall building cannot be performed. This affects the timeframe to complete the job. In an underwater maintenance, the operation cannot be performed when the depth is not safe for a human diver.

Why the existing automated/robotized solutions do not really work?

A few automated or robotized solutions have been deployed to the market. However, most people still prefer the manual solutions. Some of the reasons include the following:

Lack of adaptation capability – The existing automated/robotized solutions typically can only be used in quite specific settings, such as considerably flat surface (zero or low protrusions on the building surface). In fact, quite many buildings have significantly thick protrusions on their exterior surfaces. Furthermore, some building also have some exterior features that are difficult to be reached by the existing automated/robotized solutions.

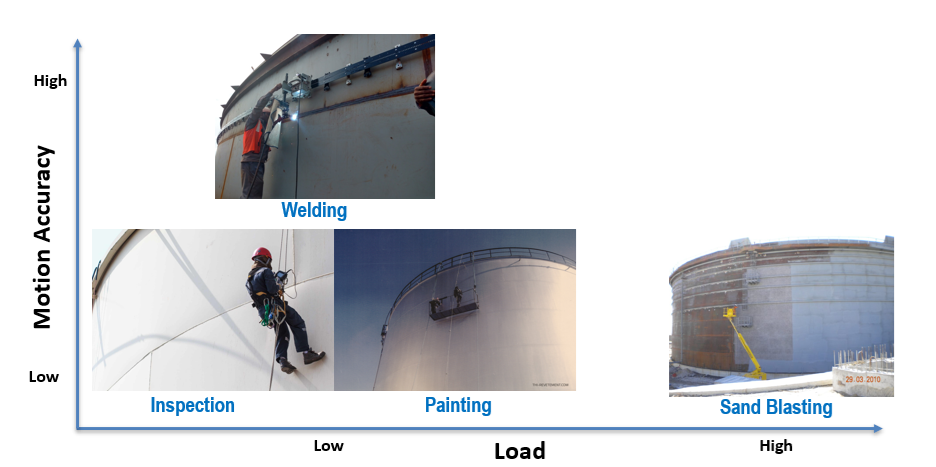

Low loading capability – In some cases, large load capability is required. For example, in deep cleaning. Most existing cleaning robots do not have this capability. Another example is sand blasting.

High capital cost – Many robotized solutions are offered with a high price tag. This makes the robotized solutions not really competitive against the manual solutions.